INKS

PLASTISOL

Plastisol ink is a type of screen printing ink made from PVC (polyvinyl chloride) and plasticizers suspended in a plasticiser medium. It’s the most commonly used ink for screen printing because of its versatility and ease of use. Plastisol inks are known for their adaptability and longevity, and are the preferred ink for a wide range of applications.

WATER-BASED

Water-based screen printing ink is made of water and pigment, rather than plastic or PVC. Water-based inks are thinner and more transparent than most other screen printing inks, so they soak into the fabric and produce a softer print that’s less likely to crack over time. Water-based inks are also flexible, soft, and can be printed on many garments.

DISCHARGE

Discharge ink is a water-based ink that bleaches the fabric of a garment, resulting in soft, vibrant prints with great color contrast. It’s made with a blend of pigments, binders, and discharge agents, which react with the fabric to break down the dye molecules. The activator removes the dyes in the shirt, stripping it to its natural fiber.

MAKE IT UNIQUE

FLOCK

Flock screen printing, also known as flocking, is the method of adding dye, adhesive, and countless tiny fiber particles (called flock) to the surface of a t-shirt or garment to create a texture.

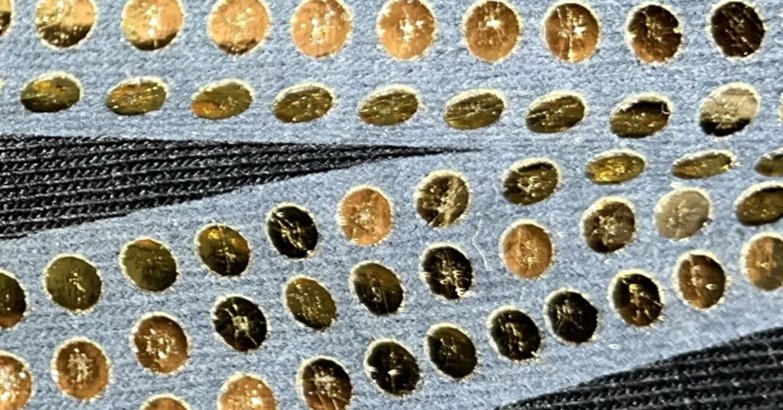

FOIL

Foil screen printing is a method that uses adhesive glue ink instead of plastisol ink, and then adds a mirror-like effect to a design. The process involves placing a foil sheet over the glue adhesive print, and then heat pressing. The heat activates the glue adhesive and grabs onto the foil, resulting in a shiny, metallic finish.

METALLIC

The process of metallic screen printing is the same as standard screen printing with the bonus of making your designs shimmer and sparkle with the use of metallic inks.

GLITTER

Glitter ink is composed of flakes of shiny foil or plastic called crystalina, usually in a plastisol base. Glitter is available for screen printing in many different sizes of flake measured in hex, or the size across the hexagonal flake in fractions of an inch.

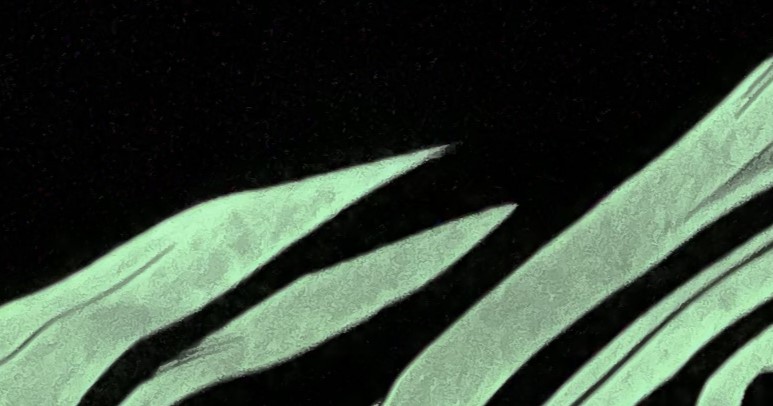

GLOW

Glow-in-the-dark screen printing is a versatile technique that uses phosphorescent inks to create designs that glow in the dark. The brightness and duration of the glow depends on the amount of ink used and the amount of sunlight or UVA light it’s exposed to. The glow is most visible in the absence of other light, so it really stands out in a dark room.

PUFF

Puff screen printing is a screen printing technique that creates a raised, three-dimensional effect by adding a puffing agent to the ink. The ink is printed using a conventional screen printing technique, then the garment is passed through the dryer, causing the ink to puff up and expand. This technique creates a sponge-like effect.

FINISHING SERVICES

FOLDING

This process uses a folding board to create consistent and precisely folded garments. Can be stacked directly in the box or polybagged. Available for T-shirts, long-sleeves, fleece crewnecks, or hoodies.

POLYBAGGING

This process places a folded garment into a clear bag to protect it during transport or to prepare for individual retail. Can be folded over for easy opening or heat sealed. Can be done in any quantity from 1-12 of any garment.

SIZE STICKERING

This process simply adds a sticker to the polybag displaying the size of the garment inside, quantity, or barcode. Available for any quantity.

TAGGING

This process adds a hangtag to your garment displaying your brand, it’s size, barcode, etc. It will arrive to you retail-ready! Available for any garment.

ADDITIONAL SERVICES

NECK LABELS

A neck label contains information about the garment such as size and care content on the inside rear of the garment around the neck area. These labels can be applied to the neck area by screen printing or heat transfer after the existing tag is removed.

EMBROIDERY

Machine embroidery is a process that uses an embroidery machine to create patterns on textiles. It’s used in many commercial applications, such as corporate advertising, product branding, and uniform adornment. It’s also used in the fashion industry to decorate apparel and garments.

SEWING

The use of a sewing machine to add tags, hem tags and labels. This is a great way to display your brand!-